3 Wheel Tester Mechanical Stress Card Testing

Two Axes 3-Wheel Test Tool

The Three-Wheel Tester is primarily designed for testing the resistance of smartcard IC chips to pressure. The T3R-E version is able to test any ID-1 cards including contactless cards and offers as an option a unique feature for querying the transponder of the card under test at each cycle, helping the analysis of test failures.

Complies with ISO/IEC 24789-2 standard and CQM v2.15 specifications (TM-421 test method) for:- Chip and atenna inlay method

- Quality control / production control of smart card

- Durability tests

Benefits

Benefits

|

Options

|

Specifications

User Interface

|

|

|

User Interface

Card Axis

Applicable Force

Weight 13 Kg

Power Supply 100-230V AC 50/60Hz

|

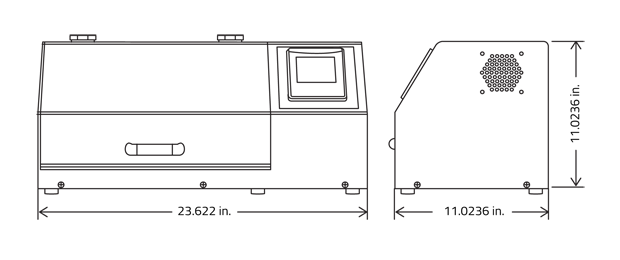

Dimensions

Notes

Note 1: The second set of weights includes one 4N, one 5N and one 10N weights for enabling additional accurate tests at 10N, 12N, 20N and 25N through combinations with standard weights. The tared (T-5N) weight shall always be present and place at the bottom for ensuring an accurate pressure value.

Note 2: The weight detector displays weight configuration on HMI for misconfiguration and pressure selection logging in the ATR.

Note 3: The contactless failure detector, query the transponder card under test (Request All command only) at each cycle and stop the test when the cardfails responding.

Note 4: Wi-Fi IEEE802.11b/g 54Mbps module, 20Mbps effective data rate over Ethernet port powered by an external 5V DC pack.

Note 5: The position helper is a label where markers have been positioned on a sticker label for helping the X positioning. For example, it locates the center of the smart card contact area when the card is return face down and the contact area no longer visible

Note 6: Full maintenance contract is subscribed after the warranty period and can be renewed annually up to 10 years maximum. Uninterrupted full maintenance contracts include annual checking and adjustments, software releases and defective pieces replacement.